The charging pile is divided into AC charging pile and DC charging pile. The one introduced below is JONCHN DC charging pile.

The DC charging pile is fixed on the outside of the electric vehicle and connected with the power grid system to convert the alternating current of the power grid into the direct current needed by the electric vehicle battery pack, commonly known as “fast charging”. It is a control device of DC working power supply, which can provide sufficient electricity, output voltage and current can be adjusted continuously, can directly charge the power battery of electric vehicle, and the charging speed is fast.

- Technical parameters of DC charging pile (taking 180kW DC pile as an example)

|

Technical index |

Specific parameters |

| Ac power supply mode | Three-phase five-wire system |

| Maximum power | 180kW |

| Ac input voltage | Rated voltage:380VAC,working range:323~437V |

| In line mode | One-way or two-way line |

| Rated output voltage | DC1000V |

| Output voltage range | DC200~1000V |

| Output current range | DC1~250A |

| Maximum output current | DC250A |

| Input power factor | ≥0.95(20%≤P<50%)

≥0.98(50%≤P≤100%) |

| Output current error | ≤±1%(Output load 20%~100% rated range)

Current≥30A,error≤±1%;Current<30A,error≤±0.3A |

| Output voltage error | ≤±0.5% |

| Ac input frequency | 50±1Hz |

| Total harmonic current | ≤5%(100% load under rated conditions) |

| Ripple peak coefficient | ≤±1% |

| Voltage stabilization accuracy | ≤±0.5% |

| Current stabilization accuracy | ≤±1% |

| Input impulse current | ≤110% Rated input current |

| Connection mode | Mode 4, connection mode C |

| Efficiency | ≥0.90(20%≤P<50%)

≥0.94(50%≤P≤100%) |

| Standby power consumption | ≤50W |

| Low voltage auxiliary power supply | Voltage:12V±5%

Rated current:10A Ripple peak coefficient:no more than±1% |

| Temperature rise of components | Meet NB/T 33001-2018 Table 2 |

| Operating temperature | -20℃~ +50℃ |

| Storage temperature | -30℃~ +55℃ |

| Humidity | 5%~95% ,there is no condensation inside the product |

| Altitude | ≤2000m |

| Installation mode | Vertical type |

| Protection grade | IP54 |

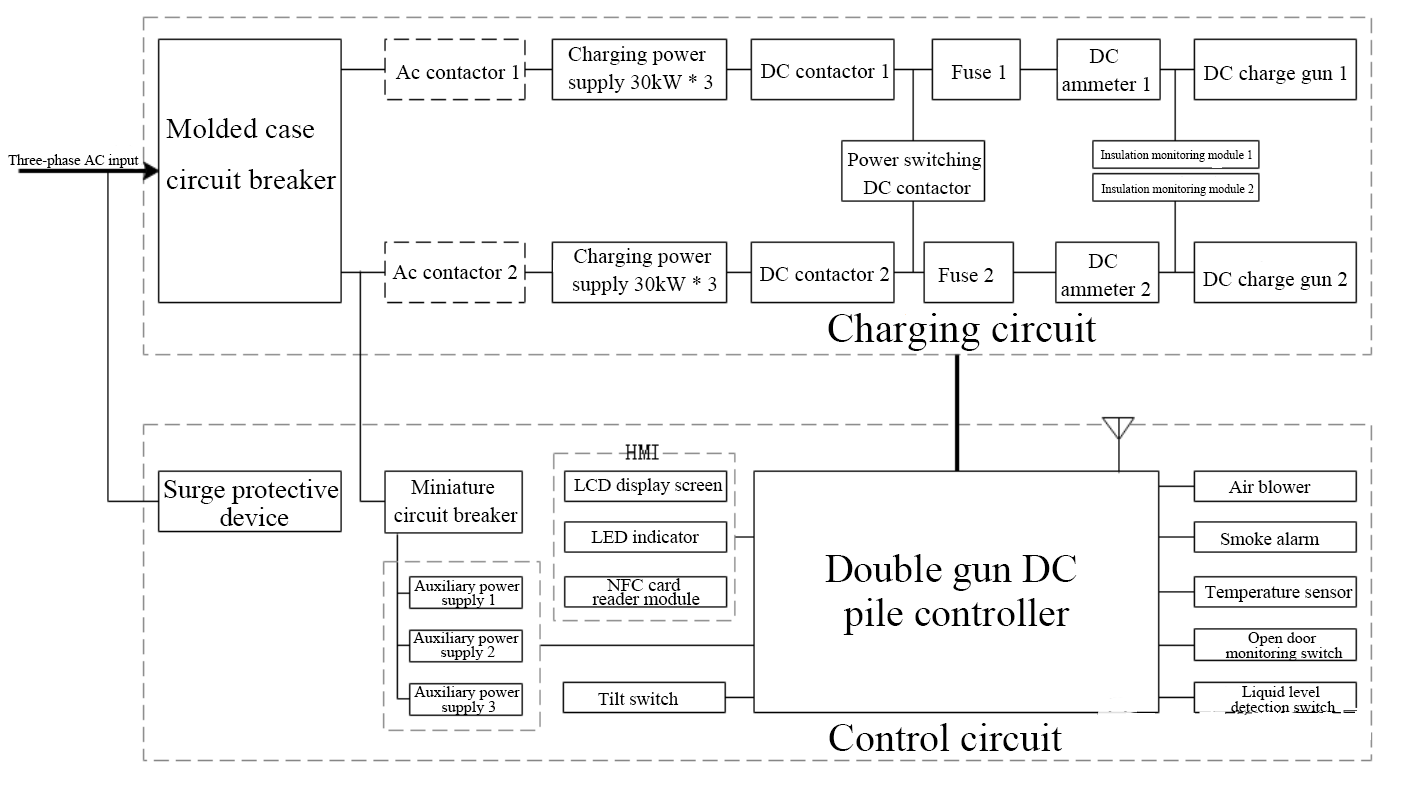

2. Block diagram of DC charging pile system

DC charging pile supplies power from three-phase AC power grid and outputs two maximum 1000V and 250A DC power supplies, which can charge electric vehicles or take turns to charge at the same time, and the maximum power of a single gun can reach 180kW.

3. Functional requirements of DC charging pile

1、Basic composition

180kW DC charging pile consists of AC input, rectifier module, output interface, insulation detection module, control module, metering module, monitoring unit, energy management unit and cabinet.

2、Communication interface and communication protocol requirements

4G communication is adopted between the 180kW DC charging post and the background communication.

The charging process of 180kW DC charging pile includes six stages: physical connection completion, low-voltage auxiliary power-up, charging handshake stage, charging parameter configuration stage, charging stage and charging end stage.

180kW DC charging pile charging communication protocol, according to GB/T 27930-2015 “Electric Vehicle Non-vehicle Conductive Charger and Battery Management System Communication Protocol“.

3、Startup mode

With contactless card reader, mobile phone APP QR code scanning.

4、Charging cable and interface

The charging cable and charging gun interface shall meet the requirements of GB T 20234.3-2015 “Connecting device for Conducting Charging of Electric Vehicles-part 3: DC Charging Interface“.

The length of the charging cable can be customized according to the demand.

5、Charging function

Charging mode setting function can be divided into automatic control charging mode and manual debugging charging mode.

6、Human-computer interaction function (optional)

It has a good man-machine interface, the display characters should be clear and complete, and can be recognized without relying on the environmental light source.

(1)Adopt 7-inch color touch widescreen with a resolution of not less than 800 × 480.

(2)The screen adopts the mode of high sensitivity touch screen and has the output of screen fault state detection.

(3)The touch screen error is ±0.5% and can be recalibrated at any time while it is in operation.

(4)To display the output function, the following information should be displayed:

Charging voltage, charging current, charging time, charging quantity, charging unit price, battery SOC,BMS demand current, voltage, status information, charging module output current, voltage, status information and other parameters, fault information, cumulative power and so on.

7、Signal detection requirements

(1) It can detect the emergency stop press status and prompt.

(2)It should be able to detect equipment failures and should be prompted accordingly.

(3)The charging pile should be able to detect the connection confirmation signal to ensure that the connection confirmation circuit is working properly.

8、Metering function

(1)The charging pile should have the function of measuring the output electric energy of each charging interface. Electric energy metering devices shall meet the relevant requirements for the verification of national measuring instruments. The meter requires that the accuracy grade of the watt-hour meter is 1.0, which meets the relevant requirements of the national standard and the identification of measuring instruments.

DC watt-hour meters should meet the GB/T 29318 measurement standard.

(2)The watt-hour meter has the communication function, the communication interface is RS485, and the communication protocol should conform to DL/T 645-2007 “Multi-function Watt-hour Meter Communication Protocol”.

(3)The background can collect the electricity data of the watt-hour meter for the equipment, and the electricity data is synchronously consistent with the interface display.

9、Data recording and uploading (4G version)

The charging pile is equipped with background networking communication function, data recording and uploading function.

(1)Fault event: the time and cause of the fault.

(2)The data stored locally by the equipment (offline data, local saved data, power-off supplementary transmission, etc.) should have the local export function and the corresponding data interface.

10、Communication and monitoring functions (4G version)

(1)Remote signal: AC/DC module AC input power failure, output fault, on / off status.

(2)Telemetry: measure the output voltage and current of the charging equipment.

(3)Remote control: the charging pile is turned on / off, which has the function of remote control charging; when the charging pile determines that it does not communicate with the monitor, the charging pile shuts down automatically.

(4)Communication connection quality requirements: it should have a reliable mechanism to detect the stability and effectiveness of communication connections, have the function of automatic detection, maintenance and management of network connections, send and receive heartbeats regularly according to parameter settings, and do not receive heartbeats during timeout. You need to disconnect the existing connection and re-establish a new one. At the same time, the data interruption of the communication does not affect the normal operation of the charging service.

11、Locking function

The charging gun should be equipped with an electronic locking device, which has a locking function to prevent accidental disconnection during charging. When the electronic lock is not reliably locked, the power supply equipment or electric vehicle should stop charging or not start charging.

12、Remote upgrade (4G version)

After networking, the charging pile burning and writing program can be controlled by monitoring operation and maintenance platform, remote one-click upgrade, remote update of all communication protocols, and new GB update and so on.

13、Safety protection function

(1)The charging pile should have the function of emergency stop, that is, in case of emergency, the AC power supply circuit can be cut off in 100ms.

(2)The output end of the charging pile should ensure that there is no current output or recharge after stopping charging.

(3)The charging pile needs to be turned on and off from the power supply and through a main circuit of the circuit breaker control equipment.

(4)It should have protection functions such as AC input over / under voltage protection, DC output over / under voltage protection, DC output voltage limit / current limit value, overload protection, short circuit protection, leakage protection, lightning protection, overheat protection, battery reverse connection, battery failure, power supply out of phase, power failure restart and so on.

1)Should have input overvoltage protection, input undervoltage protection.

2)DC output overvoltage protection, DC output undervoltage protection.

3)Output short-circuit protection: when the output end of the charging pile is short-connected, the DC output should be stopped and the alarm should be prompted; after troubleshooting, the charging pile should work normally

4)Overheat protection: the components in the integrated machine should be selected in the temperature range above industrial grade, and the alarm should be turned off when the temperature of the switch device is ≥ 85 ±5 ℃.

5)Lightning protection: there is a perfect lightning surge absorption circuit, which meets the requirements of GB 50057-2010 Building Lightning Protection Design Code 6.4.4.

6)The data sampling period of voltage and current should be less than 100ms. The period error of can communication message should be less than 10%. The falling time of 60V cut-off output of charging pile should be less than 200ms. When the demand value of charging voltage and current of BMS changes, the response time of charging pile should be less than 100A/S. After the suspension charging instruction is issued, the downtime should be less than 5s, and the protection time of vehicle connection disconnection should be less than 0.1 seconds.

7)In the process of charging, when the charging connection is abnormal, the 180kW DC charging pile should automatically cut off the output power immediately and give an alarm.

8)The charging pile should have the functions of insulation monitoring and insulation reduction alarm on the DC output side.

9)Ensure that circuits and components are not damaged in case of emergency load jump.

14、Self-test and self-recovery function

1)The charging equipment should have the functions of self-test and fault alarm, including online alarm with the background system.

2)After troubleshooting, the charging equipment should be able to restore its function automatically, but generally it should not resume charging automatically.

Post time: Apr-25-2024