Box Type Substation

Box type substation integrates high and low voltage primary equipment, transformer and secondary equipment into a double-layer, sealed, corrosion-resistant and movable outdoor box in the factory.

Box type substation, also known as prefabricated substation or prefabricated substation. It is a factory prefabricated indoor and outdoor compact power distribution equipment composed of high-voltage switchgear, distribution transformers and low-voltage power distribution devices, which are arranged according to a certain wiring scheme. That is, the functions of transformer voltage reduction and low-voltage power distribution are organically combined and installed in a moisture-proof, rust proof, dust-proof, rat proof, fire-proof, anti-theft, heat-insulating, fully enclosed and movable steel structure box, especially suitable for urban grid construction and transformation. It is a brand-new substation after the civil substation.Box type substation is applicable to mines, factories, oil and gas fields and wind power stations. It replaces the original civil power distribution room and distribution station and becomes a new complete set of power transformation and distribution equipment.

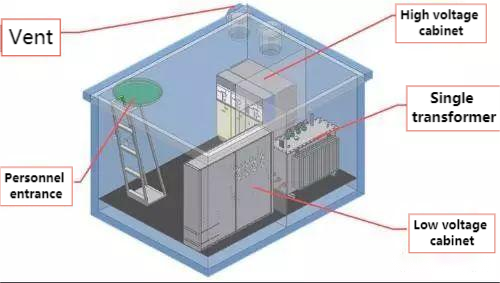

Structure of box type substation

The overall structure of the box transformer is mainly divided into three parts: high-voltage switchgear, transformer and low-voltage power distribution device.

According to the needs of the system, sulfur hexafluoride or vacuum circuit breaker, ring network switch, load switch and fuse can be selected for the high-voltage switch.

A metering device can also be installed at the high-pressure side. The main switch and shunt feeder switch are generally installed at the low-voltage side, and some only install feeder switches to directly feed the low-voltage terminal users.Compensation capacitors and metering devices can also be installed. The distribution transformer is generally oil immersed or dry-type.

The high-voltage room of European box type substation is generally composed of high-voltage load switch, high-voltage fuse and lightning arrester, which can stop and transmit power and have overload and short-circuit protection.The low-voltage room is composed of low-voltage air switch, current transformer, ammeter, voltmeter, etc. Transformers are generally oil immersed or dry-type.。

There are two forms of box, namely "mu" and "pin". The high and low voltage rooms arranged in the shape of "mu" are wide, which is convenient for realizing the ring network power supply scheme of ring network or double power supply connection.

The structure of the American box type combination transformer is divided into front and rear parts. The front part is a junction cabinet. The junction cabinet includes high and low voltage terminals, high-voltage load switches, plug-in fuses, operating handles of high-voltage tap changers, oil level meters, oil temperature meters, etc; The rear part is the oil tank body and heat sink. The transformer winding, iron core, high-voltage load switch and plug-in fuse are all in the oil tank.The box adopts a fully sealed structure. The integrated box type substation is recently developed by domestic manufacturers and is not widely used. It is a double-layer structure with high and low voltage rooms placed on the transformer room.

European type, American type and integrated box transformer have their own advantages and disadvantages. European type box transformer has a large volume. The high-voltage and low-voltage switches and transformers are all located in a large shell. The heat dissipation conditions are poor, and mechanical exhaust devices need to be installed. Because the cooling fins of the transformer directly dissipate heat to the outside, the cooling conditions of the American type box transformer are relatively good, but its shape is worse than that of the European type, and its appearance is difficult to match with the greening environment of residential quarters. The integrated box transformer occupies less land, and its advantages and disadvantages are similar to those of the American box transformer. In addition, American and integrated box type transformers can only be manufactured in China with a capacity of less than 630kVA, while European box type transformers can reach 1250kva.

Ordinary box type substation models are divided into three categories:

(1)High voltage switchgear model;

(2)Dry-type transformer cabinet model;

(3)Low voltage switchgear model.

The meaning of the first three letter symbols is:

Z-combined type; B-substation; N (W) - indoor (outdoor, optional); X-box type; Y-mobile.

Operation and maintenance of box type substation

(一)Basic requirements for operation of box type substation

1、The floor on which the box type equipment is placed shall be at a higher place rather than at a lower place, so as to prevent rainwater from pouring into the box and affecting the operation. When casting the concrete platform, a gap shall be reserved to facilitate the laying of cables.

2、There must be two reliable connections between the box and the grounding grid. The grounding and neutral connection of the box transformer can share the same grounding grid. The grounding grid is generally connected by grounding piles at four corners of the foundation.

3、Materials shall not be stacked around box type equipment in violation of regulations to ensure the ventilation of electrical equipment and the needs of operation inspection. Box type transformer shall be cooled by natural air circulation, and the transformer room door shall not be blocked.

4、The ring network switch, transformer, lightning arrester and other equipment in the high-voltage power distribution device shall be regularly inspected and maintained. Defects found shall be repaired in time. Preventive insulation test shall be conducted regularly. During the operation, the mechanical interlock shall be properly removed and the insulation rod shall be used for operation.

(二)Patrol and maintenance of box transformer the box transformer shall conduct regular patrol (not less than once a month) according to the patrol and maintenance cycle, test the temperature at the connection of cable terminals, check the equipment operation, and carry out tests if necessary.

General patrol items are as follows:

1、Whether the foundation is firmly trapped, whether the holes are blocked, and whether the cabinet has moisture.

2、Whether the grounding device is complete and well connected, and whether the grounding resistance meets the requirements.

3、Whether the outdoor environment has changed, and whether it has affected the safety of traffic and pedestrians.

4、Check the load of each feeder, whether the three-phase load is balanced or overloaded, whether the switch opening and closing position, instrument indication are correct, and whether the control device works normally.

5、Dust removal of box transformer: the inside of box transformer shall be cleaned every other year. The cabinet surface and gas box surface of HV and LV rooms can be wiped with wet cloth. The transformer in transformer room shall be cleaned with air blowing or dust collector.

6、Daily maintenance and overhaul of the fan check the operation of the fan. If it does not operate, use the temperature and humidity controller to adjust it below the existing temperature and start the fan for inspection.

7、Maintenance and repair of electric operating mechanism of high-voltage switch and low-voltage switch

(1)Check whether the pointer of the barometer is in the green area. If it is in the red area, open and close the barometer. Immediately notify the manufacturer to deal with it.

(2)For the lubrication of mechanical parts, general lithium grease (grease) can be used for opening and closing operation test after lubrication.

(3)Routine test of cable and lightning arrester according to the requirements of routine test, insulation test and leakage current test shall be conducted for cable and lightning arrester.

8、Auxiliary routine test: routine test of temperature and humidity controller; Routine test of smoke alarm device; Fastening and inspection of terminal strip: fastening and inspection of standard parts.

9、Maintenance of terminal strip: the terminal strip may become loose due to thermal expansion and cold contraction. All terminals in the terminal room shall be retightened during annual patrol inspection. Note: before retightening, please confirm that the primary ac circuit and the secondary control circuit are powered off to avoid electric shock!

10、Precautions for maintenance of box type substation

(1)The door of the box type substation is equipped with a wind proof mechanism, which is a mechanism to ensure that it is kept in a fully open state. When closing the door of the box type substation, the root of the wind proof mechanism must be lifted up, and then the door cannot be dragged mechanically to prevent the deformation of the mechanism or door, which will affect the normal use of the box type substation!

(2)After the local manual operation of the high-voltage load switch is completed, put the operating handle of the load switch back on the handle bracket inside the outer door to avoid loss.

(3)When the backup circuit of the high-voltage ring main cabinet is not connected with cables for the time being, the backup circuit shall be locked before the ring main cabinet is powered on, or the cable holder shall be blocked with a matching insulating cap to avoid accidents!

(4)The dust cap equipped with the ring main cabinet when the box transformer leaves the factory cannot replace the insulating cap!

(5)It is not allowed to insert any short-circuit plug into the test hole during operation. Otherwise, the voltage sensor will be damaged.

(6)The low-voltage disconnector can only be operated when it is in the unlocked position. Do not pull it hard

Correct operation of box type substation

1、Closing operation

Close the cable room door --- separate the grounding switch --- close the load switch.

2、Opening operation

Separate the load switch --- close the grounding switch --- open the cable room door.

Notes during operation

(1)When carrying out the opening and closing operation of the load switch, the switch must be pushed to the final opening or closing position. Do not release or pull out the operating handle before the switch completes its action, otherwise the spring rebound will hurt the operator.

(2)During the opening and closing operation of the load switch, the operating handle shall be turned outward to prevent injury to operators.

(3)Before carrying out the opening and closing operation of the load switch, the electric manual switch knob on the upper left of the corresponding unit panel must be pulled out and rotated 90 ° to the manual position before the manual operation of the load switch can be carried out, otherwise the mechanism may be damaged.

Causes and troubleshooting of fault phenomena

(1)Frame circuit breaker cannot be closed

1.Control circuit failure.

2.After the intelligent release acts, the red button on the panel does not reset.

3.Energy storage mechanism does not store energy

Exclusion method

1.Check the open point with a multimeter.

2.Find out the cause of tripping and press the reset button after troubleshooting.

3.Manual or electric energy storage.

(2)Molded case circuit breaker cannot be closed

1.The mechanism is not reset after tripping.

2.The circuit breaker is equipped with undervoltage coil and there is no power supply at the incoming end.

Exclusion method

1.Find out the cause of tripping and reset after troubleshooting

2.Electrify the incoming end, reset the handle, and then switch on.

(3)The circuit breaker trips when it is closed.

There is a short circuit in the outgoing circuit

Exclusion method

It is not allowed to switch on repeatedly. The fault must be found out and closed again after troubleshooting.

(4)The capacitor cabinet cannot compensate automatically.

1.The power supply of the control circuit disappears.

2.The current signal line is not connected correctly.

Exclusion method

Check the control circuit and restore the power supply.

Construction of box type substation

Construction of grounding device in box type substation

1、 The box type substation is surrounded by a grounding grid, which is connected to the grounding grid of surrounding buildings.

2、The buried depth and welding requirements of grounding devices shall meet the design requirements and relevant specifications.

3、 After the grounding device is installed, the grounding resistance can be tested only in sunny weather and when the ground humidity reaches the specifications. If there is a grounding device whose grounding resistance value does not meet the requirements, the corresponding grounding electrode and grounding bus shall be added as required until the grounding resistance value meets the design requirements.

4、 The connection between grounding device and equipment shall be reliable and beautiful.

Installation and construction of outdoor box type substation

1、Application for approval: order the corresponding materials and equipment according to the requirements of the box type substation design drawings and use requirements provided by the box type substation manufacturer, and provide the equipment model to the power supply department for approval before ordering the transformers in the box type substation.

2、Wiring: the reasonable incoming point of power supply shall be determined through site investigation, and the corresponding power receiving construction scheme shall be prepared.

3、Embedding: carry out the foundation construction of box type substation, and embed the corresponding components and cable protection steel pipes.

3、Installation: after the foundation reaches more than 70% of the design strength, the box type substation shall be inspected before arriving at the site. After the accessories are complete, the equipment is in good condition, and there is no corrosion or mechanical damage, the equipment can be installed. In this process, we should still pay attention to the maintenance of the foundation.

5、Inspection: after the construction of the box type substation is completed, the construction unit shall first carry out self adjustment and self inspection of the equipment, and then report to the test department with test qualification entrusted by the construction unit to enter the site to test the box type substation.

Post time: Sep-08-2022