Features

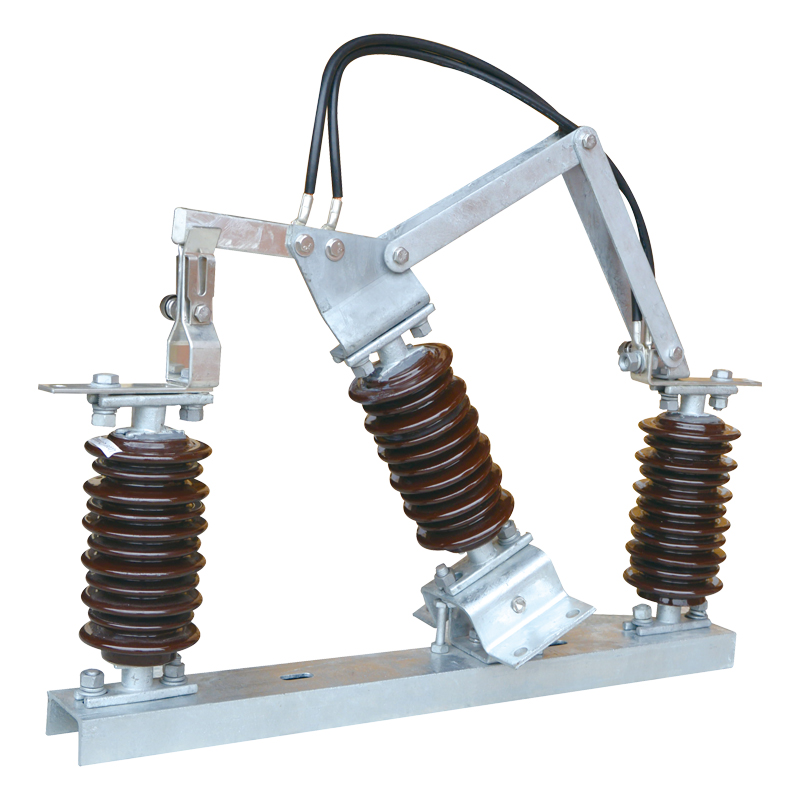

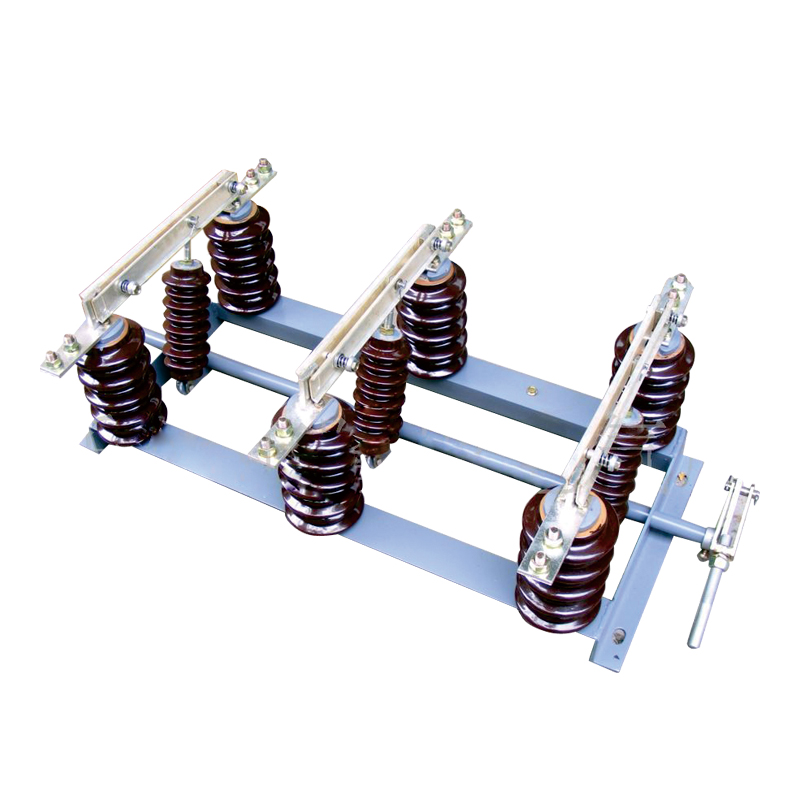

◆Isolating switch adopts the structure of double-column opening and contact transfer, which has the ability to automatically clean the contacts and improves the contact reliability;

◆The contact finger is made of new material with high strength, high conductivity and high elasticity. The contact is clamped by the elastic force of the contact finger itself, which avoids the reduction of the contact clamping force caused by the corrosion of the spring and thermal annealing. A vicious circle of increased contact resistance and increased contact heating;

◆The rotating part of the isolation switch is designed according to the requirement of maintenance-free. The rotating seat is designed as a sealed structure, water vapor, dust and harmful gases cannot enter, so that the bearing and lithium molybdenum disulfide lithium-based lithium-based grease will always work in

In a good environment, the bearing will never rust, the grease will not be lost, and it will never dry up, so that the operating torque of the isolating switch will not increase after long-term operation. Use stainless steel shaft pins to match with oil-free self-lubricating bearings Structure; the steel parts are hot-dip galvanized to ensure that the disconnector is flexible, light, reliable, and never rusted.

The description of the characteristics of the perfect isolating switch

◆All adopts hot-dip galvanizing process for anti-corrosion treatment. Hot-dip galvanizing cannot guarantee that the parts that need to be rotated are generally made of stainless steel. Fasteners below M8 are made of stainless steel, and the rest are hot-dip galvanized.

◆Conductive part of the copper tube soft connection type, the middle contact is a "handshake" type self-operated contact finger, the spring external pressure type has no current passing through, the isolation switch has only one contact point in the middle, and the rest are fixed by soft connection.

◇ Using a new contact structure, one end of the contact piece is fixed with the contact base, and the contact pressure is generated by the deformation of the contact piece and the spring, so that the sliding contact of the end of the contact finger is changed to a fixed contact, which improves the reliability of conduction;

◇The contact spring is changed to an external type to avoid spring shunting;

◇Increase the magnetic lock plate to improve the dynamic and thermal stability performance.

◆The rotating part is equipped with a self-lubricating sleeve, no need for grease.

◆The main terminal is flat type. When the current level is 630A, the surface of the conductive parts is plated with tin; when the current level is 1250A-4000A, the surface of the conductive parts is plated with silver.

◆The upper and lower caps of the porcelain pieces are hot-dip galvanized to prevent rust, and the porcelain pieces with different creepage distances can be selected according to the different pollution levels in the area; in the production process, the positive difference is controlled, and the creepage distance is designed by comparing the nominal value.

The standard value is designed to be high.

◆Strut insulators for switches have high strength and density, are stable and reliable. The formula is made of high-strength ceramic materials, which reduces the dispersion of product strength and increases the tensile strength of the product.

There is a large strength reserve, so that the product is stable and reliable in operation.

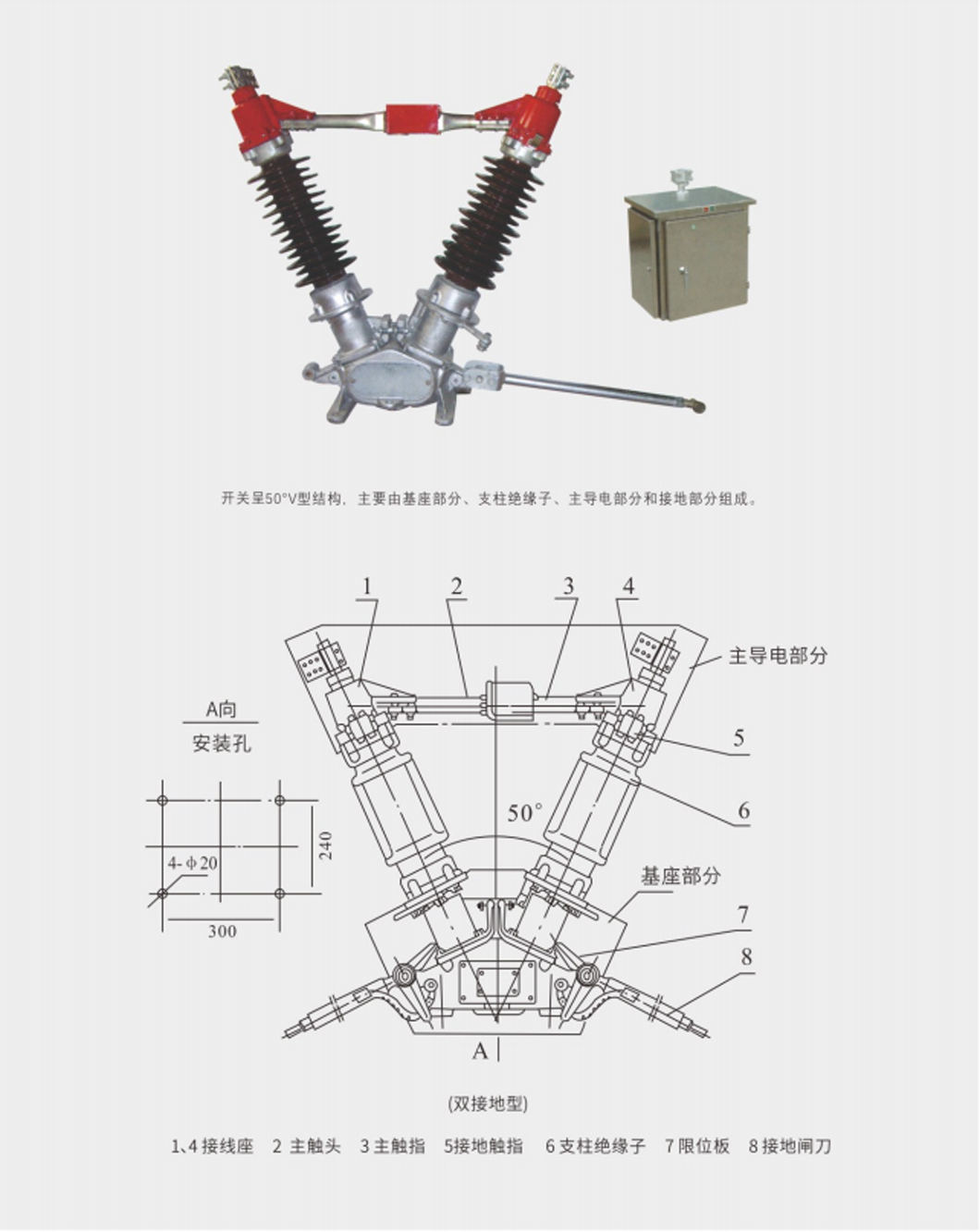

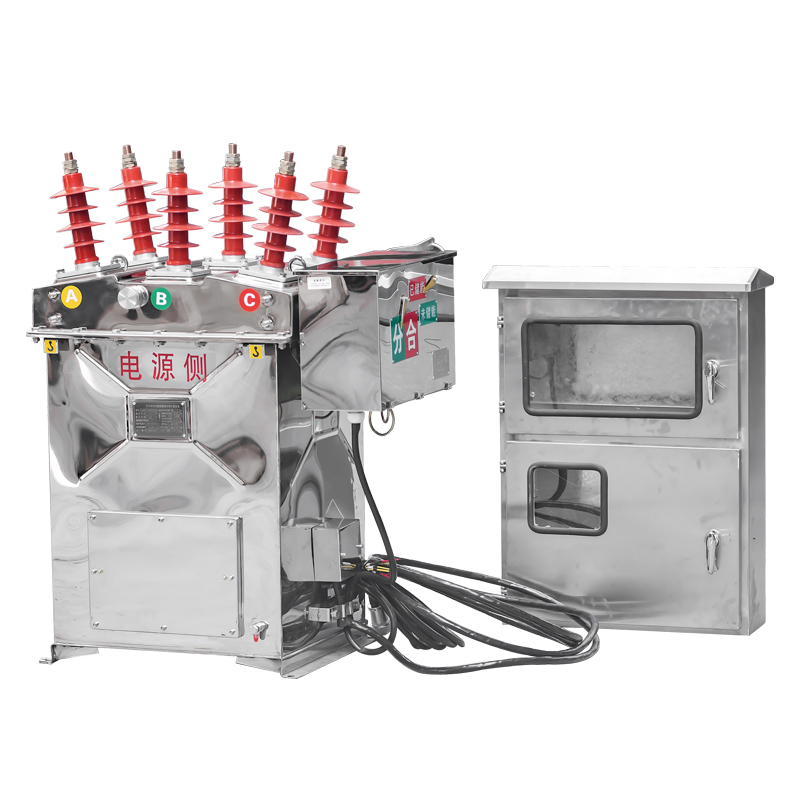

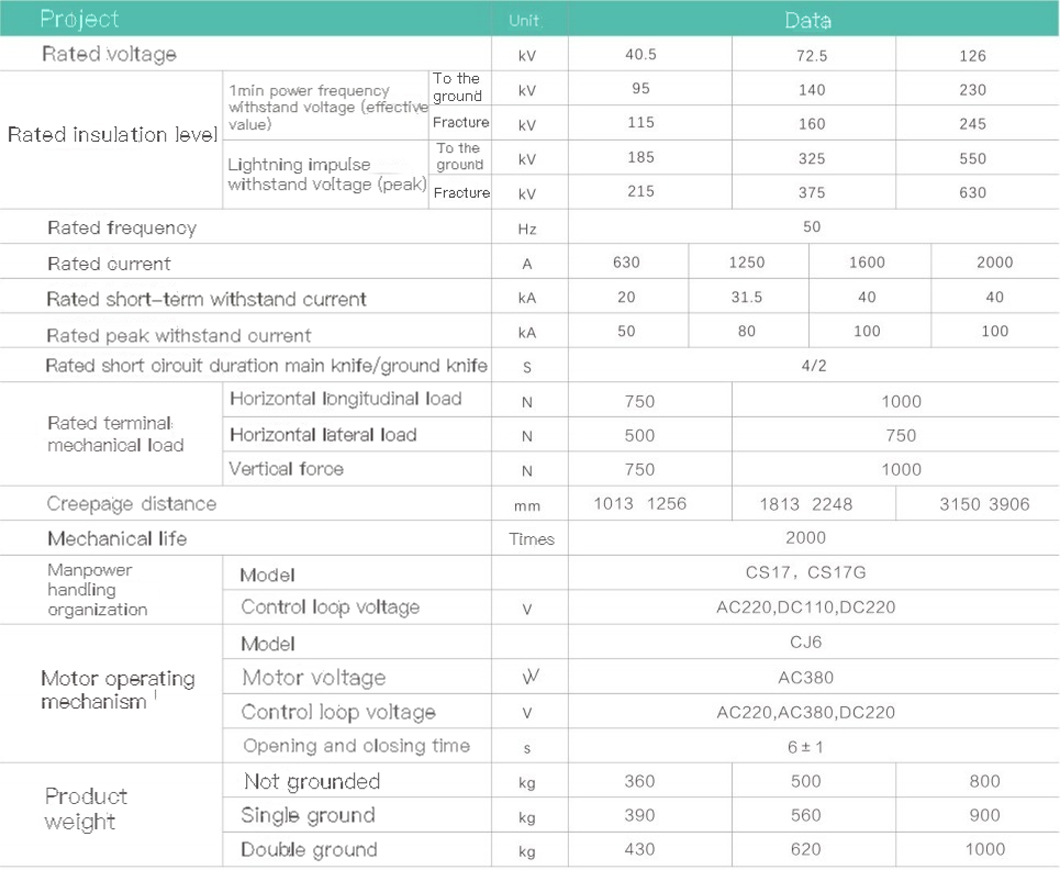

GW5-40.5、72.5、126(DW )Model outdoor high-voltage isolating switch technical parameters

GW5-35 Outdoor high voltage isolation switch